Background

Although the most familiar types of coated abrasives are probably the individual sheets of sandpaper with which home wood workers prepare furniture or crafts for painting, the trade term “coated abrasives” actually encompasses a much wider array of products for both individual and industrial use. While these products assume many forms, all are essentially a single layer of abrasive grit attached to a flexible backing. In addition to their best-known form, sandpapers are also available to consumers on belts, rolls, and disks. However, the biggest users of coated abrasives are manufacturers who employ large-scale abrasives in various phases of industrial production. For example, coated abrasives are critical in both the furniture and automotive industries.

Coated abrasives date as far back as the thirteenth century, when the Chinese used crushed shells and seeds glued with natural gum to parchment. By 1769 coated abrasive paper was being sold on the streets of Paris. An 1808 article describes a process for making coated abrasives, and in 1835 a United States patent was issued for a machine that produced coated abrasives.

Not always a highly versatile tool, coated abrasives were originally restricted to finishing applications such as polishing or preparing surfaces for painting or plating. Through improvements in the strength of backings and the properties of abrasive minerals, coated abrasives now can be used for heavy- duty applications. Today, industrial uses for coated abrasives range from hand polishing with sheets of coated abrasive to grinding steel with large machines that use 300-horse- power electric motors to drive belts several feet wide.

Currently, approximately forty companies manufacture or import jumbo rolls in the United States. The size of the industry is limited because it requires a substantial investment in equipment, raw materials, energy, and labor. A larger number of companies convert the jumbo rolls into useable products such as disks and belts.

Raw Materials

The name “sandpaper” is actually a misnomer, as most coated adhesive products contain neither sand nor paper. Generally, they consist of some type of abrasive mineral, which can be organic or synthetic; flexible backings; and adhesives. Other materials may be added for special applications. Most companies that manufacture jumbo rolls of coated abrasives purchase minerals and backing materials from independent companies that specialize in making these items. Natural minerals come from companies that mine and process the minerals, synthetic minerals come from companies that specialize in such refractory materials, and most backings come from fabric manufacturers.

The abrasive grain, the key part of coated abrasive products, may be either a natural or synthetic mineral. Due to their extreme hardness, natural minerals such as garnet or emery (corundum with iron impurities) find limited use in products for wood-related applications, while crocus mineral (natural iron oxide) is limited to use as a polishing agent because of its softness. However, such natural minerals comprise less than one percent of the abrasives market. Metalworking applications require synthetic minerals exclusively because such minerals offer consistent quality and can be specially manufactured with an elongated structure that bonds well to flexible backings.

The use of a particular coated abrasive product determines the mineral that will be used in that product. Aluminum oxide is the most common abrasive, followed by silicon carbide. Because silicon carbide is harder and sharper, it is used for applications involving glass and other nonmetal materials. Aluminum oxide, which is the tougher abrasive, is used for metalworking applications where high forces are common. Minerals containing zirconium alumina and alumina are typically used where extremely rugged abrasives are needed, such as in foundries. Expensive and extremely hard minerals such as diamond or cubic boron nitride are restricted to special polishing processes.

The sizes of abrasive grains range from fine particles that look like flour (2,000 grit) to large particles that look like granulated sugar (60 grit). Finer grains are used for surface finishing applications and larger grains for shaping and material removal applications. Recent developments in making uniform and extremely small grain abrasives with particles the size of air-born particulate in smoke have created applications in fine polishing known as super finishing. Other improvements include patented technology to cluster fine minerals into small hollow spheres or conglomerates the size of conventional grains. Such refinements have improved cutting ability and extended the useful life of coated abrasive products.

The backing is the flexible platform to which the abrasive mineral is attached. The development of coated abrasives as a versatile manufacturing tool can in part be attributed to improvements in backing materials. Without a strong and flexible backing, coated abrasives could not survive rough handling or the effects of liquids that are often used as grinding aids.

Backings come in four basic materials, each with unique attributes. Paper is the lightest of the backing materials and also the weakest. Although its lack of material strength limits paper’s usefulness for hand applications, its flexibility makes it ideal for applications in which the coated abrasive must fit closely to the contour of a work piece. Graded on a scale that increases with the physical weight of a ream, paper backings come in weights rated A to F. Unless specially treated, paper cannot be used with water or other fluids.

Backings made from woven fibers come in progressively heavier weight designations of J, X, Y, M, and H and are typically made of cotton, polyester, or rayon. The pattern of weave in the backing varies from fibers woven at 90 degree angles to fibers overlaid at 90 degree angles and stitched together. A less-common mesh or screen pattern is used for backings in materials needed in wet, low- pressure applications. Fiber backings are made of multiple layers of resin-impregnated cloth fibers that are used in some dry, high- pressure applications. Film backings, a recent development, have improved the effectiveness of coated abrasives in precision finishing. Uniformly thick synthetic film can be used with special micron-sized minerals to produce highly reflective finishing and precision dimensions on parts.

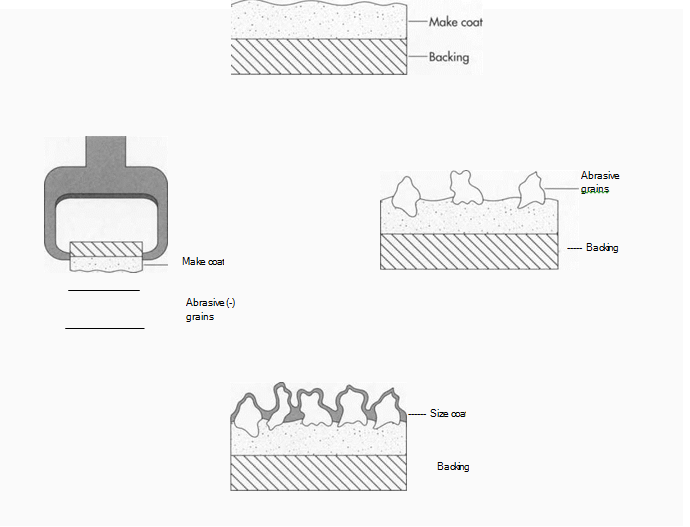

The bond or adhesive is applied to the backing in two layers, each of which serves a different purpose. The first layer of adhesive, called the make coat, holds the abrasive mineral to the backing. After the first layer of adhesive and grain have been applied, a second adhesive, the size coat, is applied in varying thicknesses depending upon the kind of product being manufactured. A thin layer of size coat leaves more of the abrasive mineral exposed, yielding a product that cuts more aggressively. Thicker layers of size coats, which cover more of the mineral, create a product that cuts less aggressively but creates finer finishes.

The Manufacturing Process

Applying the make coat to the backing

1 A typical sanding belt originates with the manufacture of a large roll of coated abrasive containing an “X” weight cotton fabric backing, 100 grit aluminum oxide, and resin bond. Production starts when the make coat is applied to one side of the backing material.

(The term “sandpaper” is a misnomer, since most coated abrasives contain neither sand nor paper. Instead, a typical coated abrasive contains a backing of cotton, polyester, or rayon, with an initial layer of adhesive backing—the make coat—applied to it. The abrasive grains are then applied using an electrostatic deposition process, in which the grains are given an electric charge. Finally, another layer of adhesive—the size coat—is applied.)

Applying the abrasive to the make coat

2 The next step, applying the abrasive mineral, is the most important in the manufacturing process because it determines the orientation and density of the mineral. In the past, the backing with the first layer of adhesive passed under a controlled stream of abrasive, which applied a thin layer of randomly oriented grit. Today, the backing is passed, adhesive side down, over a pan of abrasives that have been electrostatically charged— given an electric charge opposite to the backing. The opposite charge causes the abrasive to adhere evenly to the backing, resulting in a very sharp, fast-cutting coated abrasive tool with the maximum life possible.

3 Controlling mineral density on the flexible backing gives rise to two important variations in product design: open- and closed-coat abrasives. An open-coat product contains abrasives grains that cover from 50 to 70 percent of the surface area of the backing. This lower density allows the finished product to be flexible and prevents it from clogging or loading with bits of work material. In closed-coat products, the mineral covers 100 percent of the available surface area, making the finished products better for finishing applications and more suitable for rougher handling than open-coat products.

Applying the size coat

4 Once the grain has been imbedded in the make coat, the roll is dried and moved on for application of the size coat. Following application of the size coat, the roll is dried again and cured under carefully controlled temperature and humidity conditions. The finished product is then wound on a large spool and shipped to the companies that will convert it into sanding belts or other items.

(Sandpaper can take any number of sizes and shapes and can be used for a variety of applications, from the common hand-held sheet shown here to huge machines that use 300-horsepower electric motors to drive belts several feet wide)

5 Additional materials and processes may be included to give the converted product special characteristics. One such treatment is the addition of a grinding aid in the size coat that improves grinding of some metals in high-pressure applications. Another treatment entails applying a pressure-sensitive adhesive to the nonabrasive side of the backing to make some types of sanding disks. Material may be also added to reduce the static electricity that is generated when a belt is used on wood. Passing the roll through two closely spaced steel rollers in a process called satining crushes protruding minerals and leaves a product with uniform thickness designed for fine finishing applications.

Flexing the roll

6 Before the coated abrasive roll is converted into a belt or other product, it is systematically flexed or bent to break the continuous layer of adhesive bond. This flexing is necessary because the freshly manufactured roll is so stiff that it otherwise would not perform properly when converted into other products. Flexing can be applied in either a single direction or in multiple directions. Single direction flexing breaks the bond usually at a 90 degree angle to the edge of the roll. For special applications in which the belt must accurately conform to contours of a part surface, single direction flexing is applied along lines parallel to the sides of the belt. Multiple flexing breaks the bond at 45 degree angles to the sides of the belt in a crisscross pattern or in a combination of 90 degree and 45 degree directions. Although the latter produces a very flexible belt, such flexing greatly reduces the useful life of the product.

Conversion

7 Converting roll material into abrasive belts starts with cutting strips of coated abrasives to the desired width. Each strip is then cut to the proper length, and the ends are joined together. The joint in common belts is an overlapping splice at 45 degrees. Narrow belts are spliced at a more acute angle and wide belts at a greater angle. A variety of splicing techniques can be applied depending upon the importance of changes in belt thickness at the slice and the amount of stress the belt will receive during use. One common practice in preparing a splice for joining is skiving, a process that removes a layer of abrasive or backing from the ends of the belt. To minimize thickness of joints in products used for finishing applications, both ends are skived. Coarsegrained products, which are used for less precise applications, are skived on one end only. Conversion of other products proceeds similarly. For example, sanding disks begin with a properly sized section of roll material, and a machine punches out the individual disks complete with the hole in the center.

Quality Control

The quality of coated abrasive products is controlled by various government and voluntary standards established by trade organizations within the abrasive industry. These standards are primarily concerned with safety and with the consistent grading and identification of products. Safety standards appear in American National Standards Institute (ANSI) publication B7.7, and grain sizing and identification standards are in ANSI publication B74. 18.

The Future

Coated abrasives will continue as reliable and useful tools for the consumer and the manufactoring industry, although changes in the use of some products are likely. For example, as nonwoven abrasive products are improved and become better recognized, they may replace some coated abrasives products. Continuing development of minerals and backings will improve the performance of existing coated abrasive products. New film backing and ultra-fine abrasive minerals will enable new approaches to highly reflective and precision finishes. Also, coated abrasives will be used more with automated equipment as designs are improved and better computer controls become available.

Where To Learn More

Books

Borkowski, J. Uses of Abrasives and Abrasive Tools. Prentice Hall, 1992.

King, Robert I. and Robert S. Hahn. Handbook of Modern Grinding Technology. Chapman and Hall, 1984.

McKee, Richard L. Machining with Abrasives. Van Nostrand Reinhold, 1982.

Periodicals

Capotosto, Roberto. “Reusable Sanding Sheets,” Popular Mechanics. June, 1991, p. 73.

Flexner, Bob. “Fine Grit,” Workbench. January, 1992, p. 18.

Whiteley, Peter O. “What You Really Need to Know About Sandpaper,” Sunset. October, 1992, p. 148.