Background

Wall and floor tile used for interior and exterior decoration belongs to a class of ceramics known as white wares. The production of tile dates back to ancient times and peoples, including the Egyptians, the Babylonians, and the Assyrians. For instance, the Step Pyramid for the Pharoah Djoser, built in ancient Egypt around 2600 B.C., contained colorful glazed tile. Later, ceramic tile was manufactured in virtually every major European country and in the United States. By the beginning of the twentieth century, tile was manufactured on an industrial scale. The invention of the tunnel kiln around 1910 increased the automation of tile manufacture. Today, tile manufacture is highly automated.

The American National Standards Institute separates tiles into several classifications. Ceramic mosaic tile may be either porcelain or of natural clay composition of size less than 39 cm2 (6 in.2). Decorative wall tile is glazed tile with a thin body used for interior decoration of residential walls. Paver tile is glazed or unglazed porcelain or natural clay tile of size 39 cm2 (6 in.2) or more. Porcelain tile is ceramic mosaic tile or paver tile that is made by a certain method called dry pressing. Quarry tile is glazed or unglazed tile of the same size as paver tile, but made by a different forming method.

Europe, Latin America, and the Far East are the largest producers of tile, with Italy the leader at 16.6 million ft.2/day as of 1989. Following Italy (at 24.6 percent of the world market) are Spain (12.6 percent), Brazil and Germany (both at 11.2 percent), and the United States (4.5 percent). The total market for floor and wall tile in 1990 according to one estimate was $2.4 billion.

The United States has approximately 100 plants that manufacture ceramic tile, which shipped about 507 million ft.2 in 1990 according to the U.S. Department of Commerce. U.S. imports, by volume, accounted for approximately 60 percent of consumption in 1990, valued at around $500 million. Italy accounts for almost half of all imports, with Mexico and Spain following. U.S. exports have seen some growth, from $12 million in 1988 to about $20 million in 1990. Because the tile industry is a relatively mature market and dependent on the building industry, growth will be slow. The United States Department of Commerce estimates a three to four percent increase in tile consumption over the next five years. Another economic analysis predicts that 494 million ft.2 will be shipped in 1992, a growth of about 1 percent from the previous year. Some tile manufacturers are a bit more optimistic; an American Ceramic Society survey showed an average growth of around 36 percent per manufacturer over the next five years.

Raw Materials

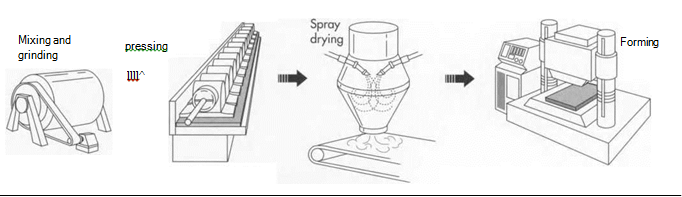

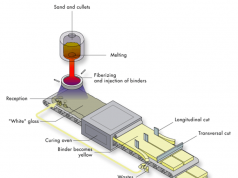

(The initial step in ceramic tile manu¬facture involves mixing the ingredi¬ents. Sometimes, water is then added and the ingredients are wet milled or ground in a ball mill. If wet milling is used, the excess water is removed using filter pressing followed by spray drying. The result¬ing powder is then pressed into the desired tile body shape.)

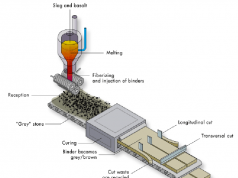

The raw materials used to form tile consist of clay minerals mined from the earth’s crust, natural minerals such as feldspar that are used to lower the firing temperature, and chemical additives required for the shaping process. The minerals are often refined or beneficiated near the mine before shipment to the ceramic plant.

The raw materials must be pulverized and classified according to particle size. Primary crushers are used to reduce large lumps of material. Either a jaw crusher or gyratory crusher is used, which operate using a hori zontal squeezing motion between steel plates or rotating motion between steel cones, respectively.

Secondary crushing reduces smaller lumps to particles. Hammer or muller mills are often used. A muller mill uses steel wheels in a shallow rotating pan, while a hammer mill uses rapidly moving steel hammers to crush the material. Roller or cone type crushers can also be used.

A third particle size reduction step may be necessary. Tumbling types of mills are used in combination with grinding media. One of the most common types of such mills is the ball mill, which consists of large rotating cylinders partially filled with spherical grinding media.

Screens are used to separate out particles in a specific size range. They operate in a sloped position and are vibrated mechanically or electromechanically to improve material flow. Screens are classified according to mesh number, which is the number of openings per lineal inch of screen surface. The higher the mesh number, the smaller the opening size.

A glaze is a glass material designed to melt onto the surface of the tile during firing, and which then adheres to the tile surface during cooling. Glazes are used to provide moisture resistance and decoration, as they can be colored or can produce special textures.

The Manufacturing Process

Once the raw materials are processed, a number of steps take place to obtain the finished product. These steps include batching, mixing and grinding, spray-drying, forming, drying, glazing, and firing. Many of these steps are now accomplished using automated equipment.

Batching

I For many ceramic products, including tile, the body composition is determined by the amount and type of raw materials. The raw materials also determine the color of the tile body, which can be red or white in color, depending on the amount of iron-containing raw materials used. Therefore, it is important to mix the right amounts together to achieve the desired properties. Batch calculations are thus required, which must take into consideration both physical properties and chemical compositions of the raw materials. Once the appropriate weight of each raw material is determined, the raw materials must be mixed together.

Mixing and grinding

2 Once the ingredients are weighed, they are added together into a shell mixer, ribbon mixer, or intensive mixer. A shell mixer consists of two cylinders joined into a V, which rotates to tumble and mix the material. A ribbon mixer uses helical vanes, and an intensive mixer uses rapidly revolving plows. This step further grinds the ingredients, resulting in a finer particle size that improves the subsequent forming process (see step #4 below).

Sometimes it is necessary to add water to improve the mixing of a multiple-ingredient batch as well as to achieve fine grinding. This process is called wet milling and is often performed using a ball mill. The resulting water-filled mixture is called a slurry or slip. The water is then removed from the slurry by filter pressing (which removes 40¬50 percent of the moisture), followed by dry milling.

Spray drying

3 If wet milling is first used, the excess water is usually removed via spray drying. This involves pumping the slurry to an atomizer consisting of a rapidly rotating disk or nozzle. Droplets of the slip are dried as they are heated by a rising hot air column, forming small, free flowing granules that result in a powder suitable for forming.

Tile bodies can also be prepared by dry grinding followed by granulation. Granulation uses a machine in which the mixture of previously dry-ground material is mixed with water in order to form the particles into granules, which again form a powder ready for forming.

Forming

4 Most tile is formed by dry pressing. In this method, the free flowing powder—containing organic binder or a low percentage of moisture—flows from a hopper into the forming die. The material is compressed in a steel cavity by steel plungers and is then ejected by the bottom plunger. Automated presses are used with operating pressures as high as 2,500 tons. Several other methods are also used where the tile body is in a wetter, more moldable form. Extrusion plus punching is used to produce irregularly shaped tile and thinner tile faster and more economically. This involves compacting a plastic mass in a high- pressure cylinder and forcing the material to flow out of the cylinder into short slugs. These slugs are then punched into one or more tiles using hydraulic or pneumatic punching presses.

Ram pressing is often used for heavily profiled tiles. With this method, extruded slugs of the tile body are pressed between two halves of a hard or porous mold mounted in a hydraulic press. The formed part is removed by first applying vacuum to the top half of the mold to free the part from the bottom half, followed by forcing air through the top half to free the top part. Excess material must be removed from the part and additional finishing may be needed.

Another process, called pressure glazing, has recently been developed. This process combines glazing and shaping simultaneously by pressing the glaze (in spray-dried powder form) directly in the die filled with the tile body powder. Advantages include the elimination of glazing lines, as well as the glazing waste material (called sludge) that is produced with the conventional method.

Drying

5 Ceramic tile usually must be dried (at high relative humidity) after forming, especially if a wet method is used. Drying, which can take several days, removes the water at a slow enough rate to prevent shrinkage cracks. Continuous or tunnel driers are used that are heated using gas or oil, infrared lamps, or microwave energy. Infrared drying is better suited for thin tile, whereas microwave drying works better for thicker tile. Another method, impulse drying, uses pulses of hot air flowing in the trans-verse direction instead of continuously in the material flow direction.

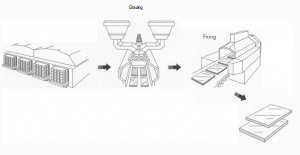

Glazing

6 To prepare the glaze, similar methods are used as for the tile body. After a batch formulation is calculated, the raw materials are weighed, mixed and dry or wet milled. The milled glazes are then applied using one of the many methods available. In centrifugal glazing or discing, the glaze is fed through a rotating disc that flings or throws the glaze onto the tile. In the bell/waterfall method, a stream of glaze falls onto the tile as it passes on a conveyor underneath. Sometimes, the glaze is simply sprayed on. For multiple glaze applications, screen printing on, under, or between tile that have been wet glazed is used. In this process, glaze is forced through a screen by a rubber squeegee or other device.

Dry glazing is also being used. This involves the application of powders, crushed frits (glass materials), and granulated glazes onto a wet-glazed tile surface. After firing, the glaze particles melt into each other to produce a surface like granite.

Firing

7 After glazing, the tile must be heated intensely to strengthen it and give it the desired porosity. Two types of ovens, or kilns, are used for firing tile. Wall tile, or tile that is prepared by dry grinding instead of wet milling (see #2 and #3 above), usually requires a two-step process. In this process, the tile goes through a low-temperature firing called bisque firing before glazing. This step removes the volatiles from the material and most or all of the shrinkage. The body and glaze are then fired together in a process called glost firing. Both firing processes take place in a tunnel or continuous kiln, which consists of a chamber through which the ware is slowly moved on a conveyor on refractory batts—shelves built of materials that are resistant to high temperatures—or in containers called saggers. Firing in a tunnel kiln can take two to three days, with firing temperatures around 2,372 degrees Fahrenheit (1,300 degrees Celsius).

For tile that only requires a single firing— usually tile that is prepared by wet milling— roller kilns are generally used. These kilns move the wares on a roller conveyor and do not require kiln furnitures such as batts or saggers. Firing times in roller kilns can be as low as 60 minutes, with firing temperatures around 2,102 degrees Fahrenheit (1,150 degrees Celsius) or more.

(After forming, the tile is dried slowly (for several days) and at high humidity, to prevent cracking and shrinkage. Next, the glaze is applied, and then the tile is fired in a furnace or kiln. Although some types of tile require a two-slep firing process, wet-milled tile is fired only once, at temperatures of 2,000 degrees Fahrenheit or more. After firing, the tile is packaged and shipped.)

8After firing and testing, the tile is ready to be packaged and shipped.

Byproducts

A variety of pollutants are generated during the various manufacturing steps; these emissions must be controlled to meet air control standards. Among the pollutants produced in tile manufacture are fluorine and lead compounds, which are produced during firing and glazing. Lead compounds have been significantly reduced with the recent development of no-lead or low-lead glazes. Fluorine emissions can be controlled with scrubbers, devices that basically spray the gases with water to remove harmful pollutants. They can also be controlled with dry processes, such as fabric filters coated with lime. This lime can then be recycled as a raw material for future tile.

The tile industry is also developing processes to recycle wastewater and sludge produced during milling, glazing, and spray-drying. Already some plants recycle the excess powder generated during dry-pressing as well as the overspray produced during glazing. Waste glaze and rejected tile are also returned to the body preparation process for reuse.

Quality Control

Most tile manufacturers now use statistical process control (SPC) for each step of the manufacturing process. Many also work closely with their raw material suppliers to ensure that specifications are met before the material is used. Statistical process control consists of charts that are used to monitor various processing parameters, such as particle size, milling time, drying temperature and time, compaction pressure, dimensions after pressing, density, firing temperature and time, and the like. These charts identify problems with equipment, out of spec conditions, and help to improve yields before the final product is finished.

The final product must meet certain specifications regarding physical and chemical properties. These properties are determined by standard tests established by the American Society of Testing and Materials (ASTM). Properties measured include mechanical strength, abrasion resistance, chemical resistance, water absorption, dimensional stability, frost resistance, and linear coefficient of thermal expansion. More recently, the slip resistance, which can be determined by measuring the coefficient of friction, has become a concern. However, no standard has yet been established because other factors (such as proper floor design and care) can make results meaningless.

The Future

In order to maintain market growth, tile manufacturers will concentrate on developing and promoting new tile products, including modular or cladding tile, larger-sized tile, slip- and abrasion-resistant tile, and tile with a polished, granite or marble finish. This is being accomplished through the development of different body formulations, new glazes, and glaze applications, and by new and improved processing equipment and techniques. Automation will continue to play

an important role in an effort to increase production, lower costs, and improve quality. In addition, changes in production technology due to environmental and energy resource issues will continue.

Where To Learn More

Books

Bender, W. and F. Handle, eds. Brick and Tile Making: Procedures and Operating Practices in the Heavy Clay Industries. Bauverlag GmbH, 1982.

Jones, J. T. and M. F. Berard. Ceramics: Industrial Processing and Testing. Iowa State University Press, 1972.

Pellacani, G. and T. Manfredini. Engineered Materials Handbook. ASM International, 1991, pp. 925-929.

Periodicals

Burzacchini, B. “Technical Developments in Ceramic Tile Glazes and Related Appli¬cations,” American Ceramic Society Bulletin. March, 1991, pp. 394-403.

Fugmann, K. “Rapid Changes in Tile Technology,” Tile & Brick International. March, 1991, pp. 165-166.

Gehringer, George. “Tile Glossary: A Guide to Techniques and Surface Designs,” American Ceramic Society Bulletin. December, 1990, pp. 1950-1952.

Geiger, Greg. “Developments in the Tile Industry,” American Ceramic Society Bulletin. December, 1991, pp. 1879-1885.