An air bag is an inflatable cushion designed to protect automobile occupants from serious injury in the case of a collision. The air bag is part of an inflatable restraint system, also known as an air cushion restraint system (ACRS) or an air bag supplemental restraint system (SRS), because the air bag is designed to supplement the protection offered by seat belts. Seat belts are still needed to hold the occupant securely in place, especially in side impacts, rear impacts, and rollovers. Upon detecting a collision, air bags inflate instantly to cushion the exposed occupant with a big gas-filled pillow.

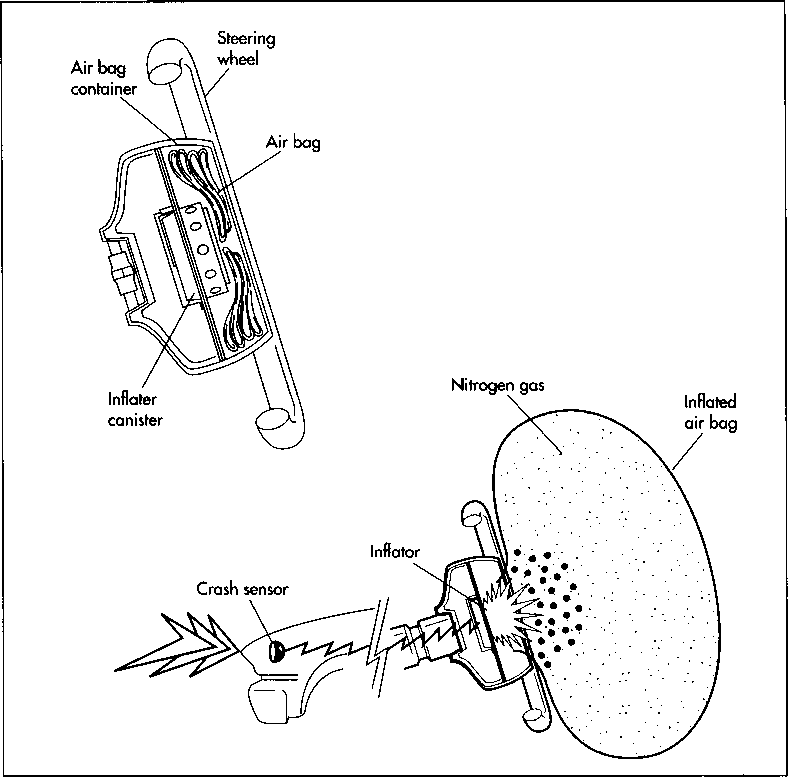

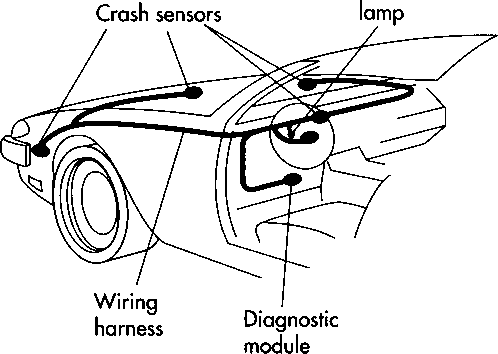

A typical air bag system consists of an air bag module (containing an inflator or gas generator and an air bag), crash sensors, a diagnostic monitoring unit, a steering wheel connecting coil, and an indicator lamp. These components are all interconnected by a wiring harness and powered by the vehicle’s battery. Air bag systems hold a reserve charge after the ignition has been turned off or after the battery has been disconnected. Depending on the model, the backup power supply lasts between one second and ten minutes. Since components vital to the system’s operation might sit dormant for years, the air bag circuitry performs an internal “self-test” during each startup, usually indicated by a light on the instrument panel that glows briefly at each startup.

The crash sensors are designed to prevent the air bag from inflating when the car goes over a bump or a pothole, or in the case of a minor collision. The inflator fits into a module consisting of a woven nylon bag and a breakaway plastic horn pad cover. The module, in turn, fits into the steering wheel for driver’s- side applications and above the glove compartment for front passenger applications.

In a frontal collision equivalent to hitting a solid barrier at nine miles per hour (14.48 kilometers per hour), the crash sensors located in the front of the car detect the sudden deceleration and send an electrical signal activating an initiator (sometimes called an igniter or squib). Like a light bulb, an initiator contains a thin wire that heats up and pen-etrates the propellant chamber. This causes the solid chemical propellant, principally sodium azide, sealed inside the inflator to undergo a rapid chemical reaction (commonly referred to as a pyrotechnic chain). This controlled reaction produces harmless nitrogen gas that fills the air bag. During deployment the expanding nitrogen gas undergoes a process that reduces the temper-ature and removes most of the combustion residue or ash.

The expanding nitrogen gas inflates the nylon bag in less than one-twentieth (1/20) of a second, splitting open its plastic module cover and inflating in front of the occupant. As the occupant contacts the bag, the nitrogen gas is vented through openings in the back of the bag. The bag is fully inflated for only one- tenth (1/10) of a second and is nearly deflated by three-tenths (3/10) of a second after impact. Talcum powder or corn starch is used to line the inside of the air bag and is released from the air bag as it is opened.

The expanding gas inflates the bag in less than one- twentieth of a second, splitting open its plastic cover and inflating in front of the occupant. The bag is fully inflated for only one-tenth of a second and is nearly deflated by three- tenths of a second after impact.

The air bag traces its origin to air-filled bladders outlined as early as 1941 and first patented in the 1950s. Early air bag systems were large and bulky, primarily using tanks of compressed or heated air, compressed nitrogen gas (N2), freon, or carbon dioxide (CO2). Some of the early systems created hazardous byproducts. One particular system used gunpowder to heat up freon gas, producing phosgene gas (COCh)—an extremely poisonous gas.

One of the first patents for automobile air bags was awarded to industrial engineer John Hetrick on August 18, 1953. Conceived by Hetrick after a near accident in 1952, the design called for a tank of compressed air under the hood and inflatable bags on the steering wheel, in the middle of the dashboard, and in the glove compartment to protect front seat occupants, and on the back of the front seat to protect rear seat passengers. The force of a collision would propel a sliding weight forward to send air into the bags. Many other inventors and researchers followed suit, all exploring slightly different designs, so that the exact technical trail from the early designs to the present system is impossible to note with certainty.

In 1968, John Pietz, a chemist for Talley Defense Systems, pioneered a solid propellant using sodium azide (NaNs) and a metallic oxide. This was the first nitrogen generating solid propellant, and it soon replaced the older, bulkier systems. Sodium azide in its solid state is toxic if ingested in large doses, but in automotive applications is carefully sealed inside a steel or aluminum container within the air bag system.

Since the 1960s, air bag-equipped cars in controlled tests and everyday use have demonstrated the effectiveness and reliability. The Insurance Institute For Highway Safety conducted a study of the federal government’s Fatal Accident Reporting System using data from 1985 to 1991, and concluded that driver fatalities in frontal collisions were lowered by 28 percent in automobiles equipped with air bags. According to another study conducted in 1989 by General Motors, the combination of lap/shoulder safety belts and air bags in frontal collisions reduced driver fatalities by 46 percent and front passenger fatalities by 43 percent.

An air bag module has three main parts: the air bag, the inflator, and the propellant. The air bag is sewn from a woven nylon fabric and can come in different shapes and sizes depending on specific vehicle requirements. The driver’s-side air bag material is manufactured with a heat shield coating to protect the fabric from scorching, especially near the inflator assembly, during deployment. Talcum powder or com starch is also used to coat the air bag; either substance prevents the fabric from sticking together and makes it easier to assemble. Newer silicone and urethane coated air bag materials require little or no heat shield coating, although talcum powder or com starch will probably still be used as a processing aid.

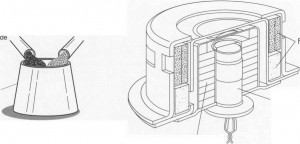

The inflator canister or body is made from either stamped stainless steel or cast aluminum. Inside the inflator canister is a filter assembly consisting of a stainless steel wire mesh with ceramic material sandwiched in between. When the inflator is assembled, the filter assembly is surrounded by metal foil to maintain a seal that prevents propellant contamination.

In response to consumers’ increased safety concerns and insurance industry pressure, the federal government has forced automobile manufacturers to upgrade their safety features. First, Department of Transportation (DOT) regulations require all cars, beginning with model year 1990, sold in the United States to be equipped with a passive restraint system. (Passive restraint systems—requiring no activation by the occupant—involve the use of automatic seat belts and/or the use of air bags.) If car manufacturers choose an air bag, then regulations require only a driver’s side system until model year 1994, when air bag-equipped cars must include passive protection on the passenger’s side as well. A 1991 law requires driver and passenger air bags in all cars by the 1998 model year and in light trucks and vans by 1999.

Raw Materials

As stated above, an air bag system consists of an air bag module, crash sensors, a diagnostic monitoring unit, a steering wheel connecting coil, and an indicator lamp. Both this section and the next (“The Manufacturing Process”) will focus on the air bag module itself.

An air bag module has three main parts: the air bag, the inflator, and the propellant. The air bag is sewn from a woven nylon fabric and can come in different shapes and sizes depending on specific vehicle requirements. The driver’s-side air bag material is manufactured with a heat shield coating to protect the fabric from scorching, especially near the inflator assembly, during deployment. Talcum powder or com starch is also used to coat the air bag; either substance prevents the fabric from sticking together and makes it easier to assemble. Newer silicone and urethane coated air bag materials require little or no heat shield coating, although talcum powder or com starch will probably still be used as a processing aid.

The inflator canister or body is made from either stamped stainless steel or cast aluminum. Inside the inflator canister is a filter assembly consisting of a stainless steel wire mesh with ceramic material sandwiched in between. When the inflator is assembled, the filter assembly is surrounded by metal foil to maintain a seal that prevents propellant contamination.

The propellant, in the form of black pellets, is primarily sodium azide combined with an oxidizer and is typically located inside the inflator canister between the filter assembly and the initiator.

The Manufacturing Process

Air bag production involves three different separate assemblies that combine to form the finished end product, the air bag module. The propellant must be manufactured, the inflator components must be assembled, and the air bag must be cut and sewn. Some manufacturers buy already-made components, such as air bags or initiators, and then just assemble the complete air bag module. The following description of the manufacturing process is for driver-side air bag module assembly. Passenger-side air bag module assemblies are produced slightly differently.

Propellant

1 The propellant consists of sodium azide mixed together with an oxidizer, a substance that helps the sodium azide to burn when ignited. The sodium azide is received from outside vendors and inspected to make sure it conforms to requirements. After inspection it is placed in a safe storage place until needed. At the same time, the oxidizer is received from outside vendors, inspected, and stored. Different manufacturers use different oxidizers.

2 From storage, the sodium azide and the oxidizer are then carefully blended under sophisticated computerized process control. Because of the possibility of explosions, the powder processing takes place in isolated bunkers. In the event safety sensors detect a spark, high speed deluge systems will douse whole rooms with water. Production occurs in several redundant smaller facilities so that if an accident does occur, production will not be shut down, only decreased.

3 After blending, the propellant mixture is sent to storage. Presses are then used to compress the propellant mixture into disk or pellet form.

Inflator assembly

4 The inflator components, such as the metal canister, the filter assembly— stainless steel wire mesh with ceramic material inside—and initiator (or igniter) are received from outside vendors and inspected. The components are then assembled on a highly automated production line.

5 The inflator sub-assembly is combined with the propellant and an initiator to form the inflator assembly. Laser welding (using CO2 gas) is used to join stainless steel inflator subassemblies, while friction inertial welding is used to join aluminum inflator subassemblies. Laser welding entails using laser beams to weld the assemblies together, while friction inertial welding involves rubbing two metals together until the surfaces become hot enough to join together.

6 The inflator assembly is then tested and sent to storage until needed.

Air bag

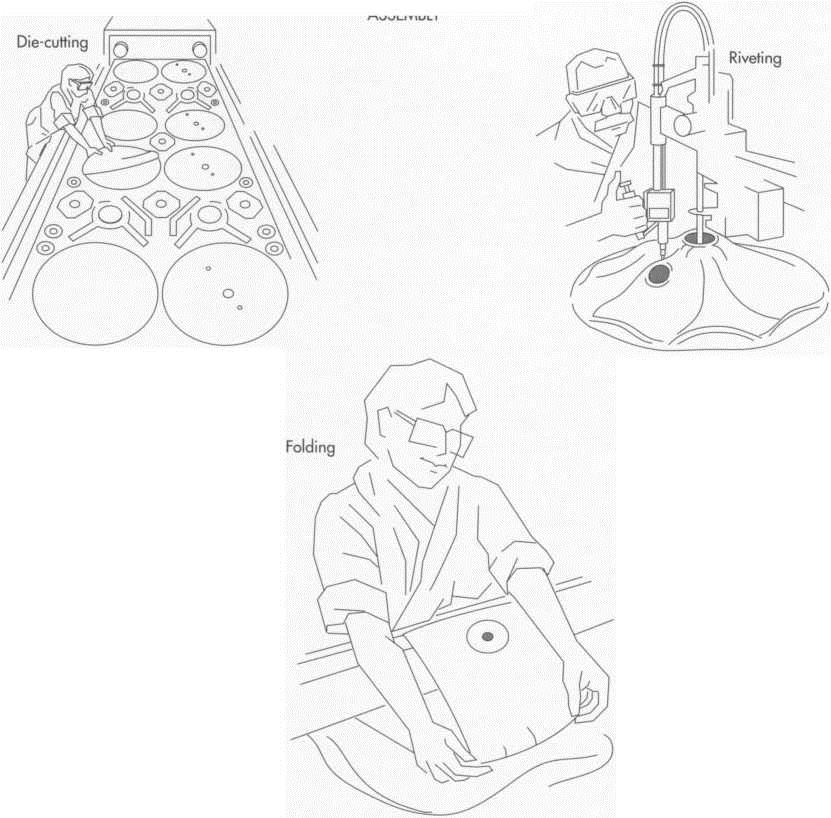

7 The woven nylon air bag fabric is received from outside vendors and inspected for any material defects. The air bag fabric is then die cut to the proper shapes and sewn, internally and externally, to properly join the two sides. After the air bag is sewn, it is inflated and checked for any seam imperfections.

Final assembly of air bag module

8 The air bag assembly is then mounted to the tested inflator assembly. Next, the air bag is folded, and the breakaway plastic horn pad cover is installed. Finally, the completed module assembly is inspected and tested.

9 The module assemblies are packaged in boxes for shipment and then sent to customers.

Other components

10 The remaining components of the air bag system—the crash sensors, the diagnostic monitoring unit, the steering wheel connecting coil, and the indicator lamp—are combined with the air bag module during vehicle assembly. All the components are connected and communicate through a wiring harness.

file air bag parts are die-cut out of woven nylon, sewn together, and riveted. The bag is then carefully folded so that it will fit inside the plastic module cover.

Quality Control

The quality control aspect of air bag production is, obviously, very important because many lives depend on the safety feature. Two major areas where quality control is critical are the pyrotechnic or propellant tests and the air bag and inflator static and dynamic tests.

Propellants, before being inserted into inflators, are first subjected to ballistic tests to predict their behavior. A representative sample of inflators are pulled from the production line and tested for proper operation by a full- scale inflator test, which measures pressure— created by the generated gas inside a large tank 15.84 or 79.20 gallons (60 or 300 liters)—versus time in milliseconds. This gives an indication of the inflator system’s ability to produce an amount of gas at a given rate, ensuring proper air bag inflation. The air bags themselves are inspected for fabric and seam imperfections and then tested for leaks.

Automated inspections are made at every stage of the production process line to identify mistakes. One air bag manufacturer uses radiography (x-rays) to compare the completed inflator against a master configuration stored in the computer. Any inflator without the proper configuration is rejected.

Crash sensors can be located in several spots on the front of the automobile. These sensors are connected to the air bag module with a wiring harness. Two other key components of an air bag system are the diagnostic module and the indicator lamp. The diagnostic module performs a system test each time the car is started, briefly lighting up the indicator lamp mounted on the dashboard

The Future

The future for air bags looks extremely promising because there are many different applications possible, ranging from aircraft seating to motorcycle helmets. The air bags of the future will be more economical to produce and lighter in weight; will involve smaller, more integrated systems; and will use improved sensors.

Side-impact air bags are another possibility that would work similar to driver- and passenger side air bags. Side-impact air bags will most likely be mounted in the car door panels and deployed towards the window during impact to protect the head. Foam padding around the door structure would also be used to cushion the upper body in a side impact. Head and/or knee bolsters (energy absorbing pads) to complement the air bag system are also being investigated. Rear-seat air bags are also being tested but consumer demand is not expected to be high.

Aftermarket air bag systems—generic systems that can be installed on any vehicle already built—are not currently available. Since the effectiveness of an air bag depends on its sensors recognizing if a crash is severe enough to trigger deployment, a system must be precisely tuned to the way a specific car model behaves in a crash. Still, companies are exploring the future possibility of producing a modified air bag system for retrofit.

A hybrid inflator is currently being tested that uses a combination of pressurized inert gas (argon) and heat from a propellant to significantly expand the gas’s volume. These systems would have a cost advantage, since less propellant could be used. Air bag manufacturers are also developing systems that would eliminate the sodium azide propellant, which is toxic in its undeployed form. Work is also underway to improve the coatings that preserve the air bag and facilitate its opening. Eventually the bags may not need coatings at all.

In the future, more sophisticated sensors called “smart” sensors will be used to tailor the deployment of the air bag to certain conditions. These sensors could be used to sense the size and weight of the occupant, whether the occupant is present (especially in the case of passenger-side air bags where deployment may be unnecessary if there are no passengers), and the proximity of the driver to the steering wheel (a driver slumped over the steering wheel could be seriously injured by an air bag deployment).

Where To Learn More

P&riodicals

Chaikin, Don. “How It Works—Airbags,” Popular Mechanics. June, 1991, p. 81.

Frantom, Richard L. “Buckling Down on Passenger Safety,” Design News. October 2, 1989, pp. 116-118.

Gottschalk, Mark A. “Micromachined Airbag Sensor Tests Itself,” Design News. October 5, 1992, p. 26.

Grable, Ron. “Airbags: In Your Face, By Design,” Motor Trend. January, 1992, pp. 90-91.

Haayen, Richard J. “The Airtight Case for Air Bags,” Saturday Evening Post. November, 1986.

Reed, Donald. “Father of the Air Bag,” Automotive Engineering. February, 1991, p. 67.

Sherman, Don. “It’s in the Bag,” Popular Science. October, 1992, pp. 58-63.

Spencer, Peter L. “The Trouble with Air Bags,” Consumers’ Research. January, 1991, pp. 10-13