Background

A compact disc, also popularly known simply as a CD, is an optical storage medium with digital data recorded on its surface. A compact disc player is a device that reads the recorded data by means of an optical beam and accurately reproduces the original information (music, pictures, or data). Because the player reads the information by optical means, there is no physical wear and tear on the disc. The basic technology used in all compact disc players is essentially the same, whether the player is designed for audio, video, or computer applications. This article will focus on players designed for audio (specifically, home audio) applications.

The history of the compact disc system can be traced back to the early 1970s, when rapid advancement in digital electronics, laser optics, and large scale integration (LSI) technologies took place. Many companies started exploring the possibility of storing audio signals in optical form using digital rather than analog means. A practical method of modulating the audio signals was found using theories published in 1948 by a scientist named Claude E. Shannon. This method, known as Pulse Code Modulation (PCM), samples audio signals during a short time interval and then converts the samples into numerical values for storage in digital format.

The storage of audio in digital format (known as audio encoding) requires large amounts of data. For example, storing one second of audio information requires one million bits of data. Optical discs capable of storing billions of bits of data in a very small area were found ideal for such applications. An optical disc can store up to one million bits of data on an area as small as a pinhead.

Once the technologies for recording and storing digital audio were found, manufacturers started looking for ways to read and process the data stored in such a small area. Experiments with laser devices (a laser emits a very narrow beam of light capable of focusing on a very small area) proved quite successful. The development of LSI techniques meant that the huge amount of data stored on the disc could be processed fast enough to provide continuous music. The stage was now set for the development of a complete compact disc system.

Although many companies participated in early research and experimentation with the various technologies involved in a compact disc system, two companies—Sony of Japan and Philips of the Netherlands—are credited with successfully merging these technologies into a complete system. The two companies collaborated to develop specific standards for the compact disc system, and a consortium of 35 manufacturers agreed to adopt these standards in 1981. The first compact disc players were introduced in the European and Japanese markets in late 1982 and in the United States in early 1983.

Raw Materials

A compact disc player is a very sophisticated piece of electronic equipment. The simple exterior contains complex interior mechanisms to read and process audio signals into very clear and crisp music. The various components include a housing cabinet, an optical pick-up assembly, and printed circuit boards (PCBs), which contain microchips that direct the electronic processes of the system.

The cabinet that houses the maze of components is usually made of light, reinforced aluminum. The laser is a small glass tube filled with gas and a small power supply to generate a laser beam, while the photodiode—a semiconducting part that the light that is reflected from the compact disc into an electrical signal—is generally made of silicon or germanium. The lenses and mirrors in the optical pick-up are made of highly polished glass or plastic. This assembly is housed in its own plastic enclosure. The majority of the electronic components—resistors, transistors, and capacitors—are contained on microchips attached to PCBs. The base material of these components is usually silicon. The hardware that connects the various subassemblies together consists of a variety of metal and plastic nuts, screws, washers, pulleys, motors, gears, belts, and cables.

Design

A compact disc is a 4.75 inch-diameter (12.065 centimeters) polycarbonate plastic disc containing approximately 74 minutes of audio information. Not all the information on the disc is music; some of it is used for error detection, synchronization, and display purposes. Information on a CD is encoded on a spiral track in the form of indentations called lands and pits that represent binary highs and lows. It is these indentations that the CD player’s laser “reads.”

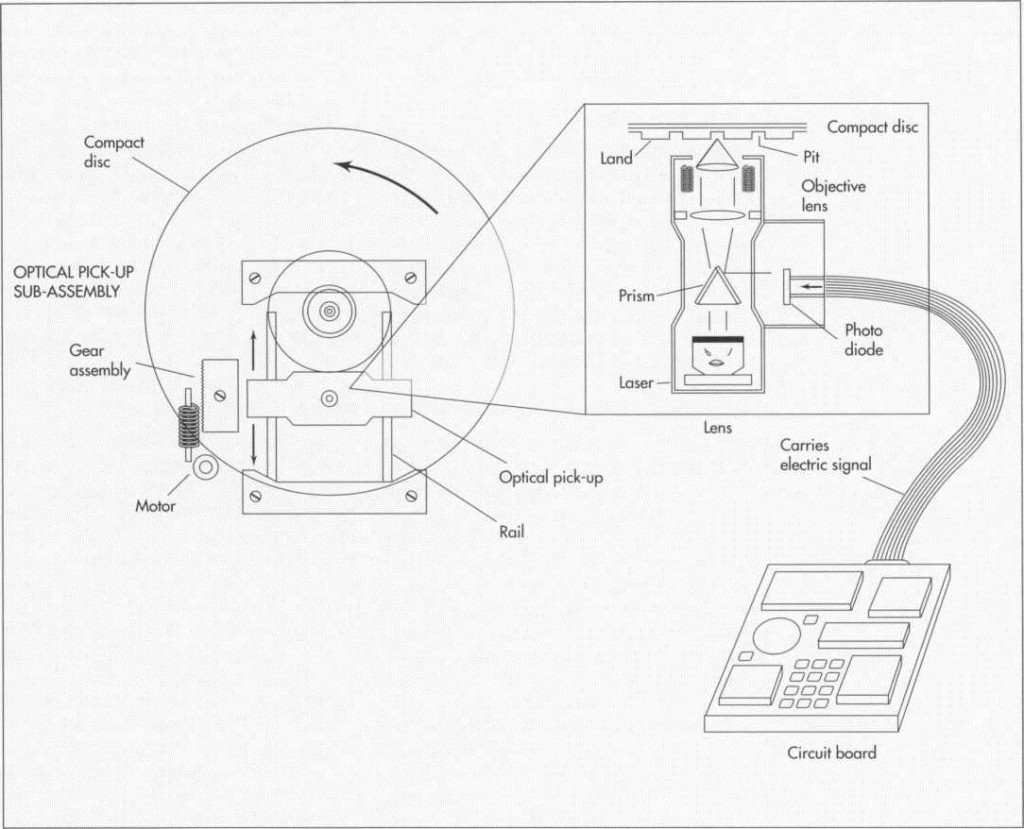

Conceptually, the design of a CD player resembles that of a phonograph (record) player. Like a record, the compact disc is rotated on a turntable, and the audio is read by a pick-up device. However, unlike a record player, the motor does not rotate the turntable at a constant speed but adjusts it in accordance with the distance of the pick-up from the center of the turntable. Furthermore, the pick-up device in a CD player is not a mechanical stylus (a needle) but an optical laser beam that does not come into physical contact with the compact disc. This laser focuses its beam on the disc track that contains the lands and pits, and the CD player’s detector (the photodiode) senses the difference between the light reflected from the lands and that reflected by the pits. The photodiode turns this reflected light into an electrical signal. Relayed to the electronic circuit board, this signal is then converted back to sound.

There are basically three subassemblies in a compact disc player: the disc drive mechanism assembly; the optical pick-up assembly; and the electronic circuit board assembly, which coordinates the other systems inside the player and which includes the servo mechanism and data decoding circuitry. By sending signals to the servo mechanism, the circuit board adjusts the motor speed, focusing, and tracking of the optical pick-up; manages the flow of data to the decoding circuitry; and provides display information in response to the various buttons on the control panel.

The disc drive mechanism consists of a spindle that holds the CD and a motor that rotates it. The motor, called the spindle motor, is mounted underneath the plastic disc loading tray or turntable. A separate motor mounted on the chassis (the base or frame of the CD player) moves the loading tray in and out of the player; this is done by means of a gear that is attached to the motor and that also operates a larger gear to raise and lower a clamp for holding the disc in place.

The optical pick-up consists of a laser, a photodiode, and various lenses and mirrors. The entire subassembly slides back and forth on rails and is controlled by the servo mechanism that receives directing signals from the circuit board. The optical pick-up is usually located underneath the clamp that positions the disc, while the motor that moves the assembly is mounted on the chassis close to the rails. The mechanism works by directing a laser beam through lenses and mirrors onto the underside of the compact disc. The lenses and mirrors keep the beam properly focused. If the beam hits a pit on the disc, no light is reflected and the photodiode remains disengaged. If the beam hits a land, light is reflected back through the lenses and mirrors onto the photodiode, which then generates an electrical signal. This signal is transferred to the electronic circuit board assembly, where it is converted by the data decoding system into audio signals for playback.

The electronic circuit board assembly consists of printed circuit boards that contain the circuitry for the servo mechanism, which operates the optical pick-up system, data decoding, and control system. There are many integrated circuits chips, microprocessors, and large scale integrated components on the board assembly

(A key assembly in a compact disc player is the optical pick-up assembly. It is situated on rails so that it can move back and forth underneath the compact disc. It works by directing a laser beam at the CD; if the laser hits a land, the reflected light then travels to the photodiode, which generates an electrical signal. In turn, the signal moves to the CD player’s circuit board, which converts the signal into music)

The Manufacturing Process

In today’s manufacturing environment there is no single method of manufacture and assembly. Products are increasingly made as subassemblies and brought together as larger subassemblies or as the final product. Robotics and computer run lines allow for virtually any part to be installed in any state of the subassembly at any point in the process. The sequence can be changed in minutes to allow for modifications or quality control check points. The manufacturing process detailed here, therefore, follows a similar approach to the actual manufacturing process used in the industry. The process is first described in terms of the various subassemblies and then the description details how the various subassemblies are brought together to make the final product.

Optical pick-up subassembly

1 Purchased from outside contractors, the laser and the photodiode are installed beneath the disc clamp. The various lenses and mirrors in the assembly must be properly spaced and aligned so that they can focus and direct light as necessary. The whole assembly is then housed in a plastic case. The case is made by the one of the usual plastic forming processes such as extrusion or injection molding, while the lenses and mirrors (usually silicon) are cut into the proper shape and then finely polished with abrasives. The semiconducting photodiode is made by preparing and polishing a substance such as silicon or germanium and then adding impurities to create layers. Electrical contacts are then added. After the optical components are in position, the gears and belt that will help to position the optical pick-up are put in place.

Disc drive subassembly

2 Next, the motor that will move the optical pick-up is connected to the gears and belt and placed on the chassis. The loading tray is now centered, and the spindle motor that will rotate the disc is installed. After the clamp to which the optical pick-up has been attached is positioned adjacent to the loading tray, the tray, clamp, and pick-up motor are installed in the loading drawer, which is placed in the CD player’s cabinet.

Electronic circuit board subassembly

3 Last to be assembled are the electronic components. Designed by engineers using computer-aided design (CAD) packages, the circuit boards consist of a copper- clad base that has a pattern transferred onto it (masking) through screen printing or a similar method. After being coated with a photosensitive material, the patterned areas are etched away chemically to create a multilayered board—the layers comprise the various transistors and capacitors that make up the circuits. The tiny microchips (usually made of silicon) that are mounted on the board are made in the same way, except on a much smaller scale. Depending on the manufacturer, the CD player may have one large circuit board or several smaller boards. After they have been attached to the panel or panels, the circuits are attached to the CD player’s front control panel, the switch assembly, and finally the power supply.

Final assembly

4 Once the various subassemblies are ready, they are connected and interfaced together to complete the final assembly. Most of the work performed at this stage is done by human workers. The CD player is now tested and sent for packaging.

Quality Control

As previously noted, a compact disc player is a very sophisticated device, and strict quality control measures are adopted from the initial to the final stage of the manufacture to ensure the proper functioning of the player in accordance with industry standards.

Because so many of the components in a compact disc player are made by specialized vendors, the player manufacturer must depend on these vendors to produce quality parts. Some of the most crucial elements are those in the optical pick-up assembly. The lenses and mirrors used in the laser pick-up, for instance, are made of high quality glass, and human contact must be avoided during the manufacturing process to keep their surfaces clean and smudge free. Similarly, the electronic circuit components must be made in a “clean room” environment (containing special air filters as well as clothing requirements), because even a single dust particle can cause malfunctioning in the circuitry. The circuit boards and chips are tested at many levels by diagnostic machines to pinpoint faults in the circuits.

As for quality control by the player manufacturer, the disc drive assembly is inspected for proper alignment of the motor, spindle, loading tray, and the various gears. In addition, the optical pick-up is checked for proper alignment of lenses and the laser beam. Once the subassemblies are tied together in the cabinet, all wiring connections are inspected for proper electrical contact and correct interface with the other components. Visual inspections to check belts, pulleys, and gears are an integral part of the quality control process. The final inspection consists of playing a test disc that generates special signals and patterns, enabling workers to track down faults in the system. In addition, the various front panel switches and buttons are checked to ensure that they perform the functions indicated and display the appropriate information on the panel.

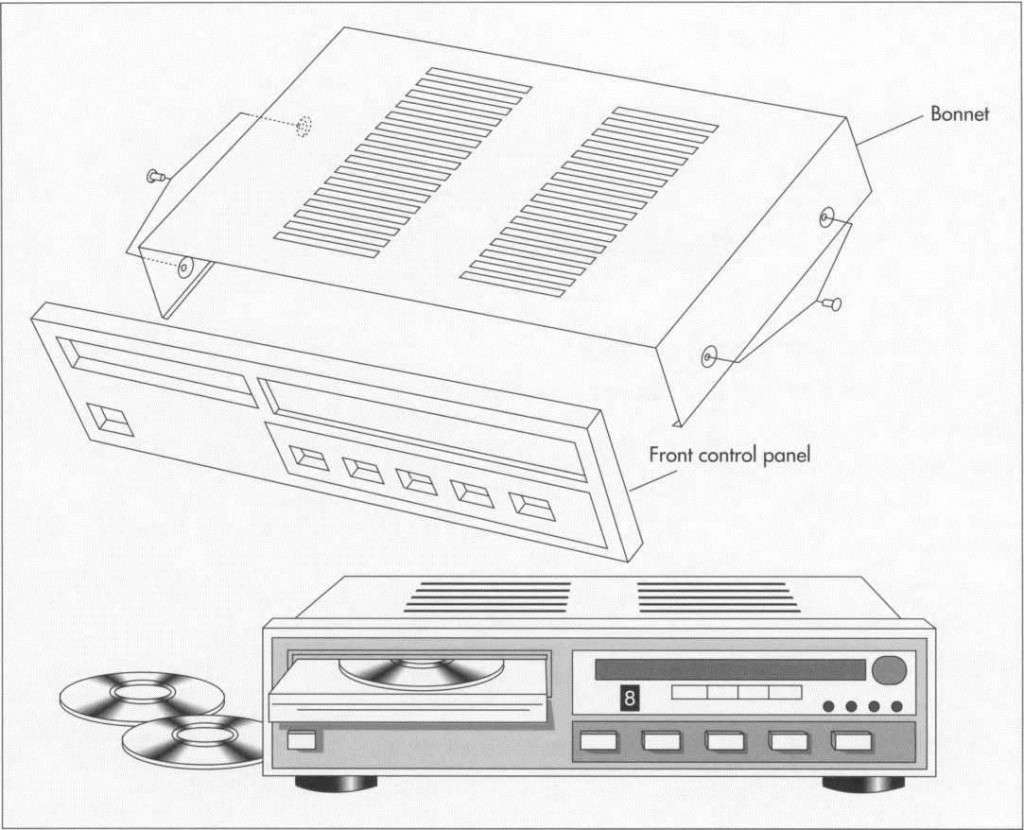

(The housing for a CD player includes a top cover or “bonnet” and a front control panel. The compact disc rests on a loading tray that slides in and out of the player.)

The Future

The CD system technology has come a long way in the last few years, and new applications for compact disc systems are being discovered every day. The market has already seen the introduction of CD-ROMs, CD- Videos and CD-Interactive. The latest product to attract consumer attention is Kodak’s Photo-CD, which can display photographs on television and computer screens. These pictures can be edited or cropped by the user, just like clip art images.

Audio CD systems will see the introduction of many new features in the coming years. Players featuring advanced remote control functions are now in the development stage.

These functions will allow the user to display information on the remote control unit itself, such as song titles, artist names, and the actual lyrics of the songs. Compact discs capable of both recording and playback, like a cassette tape, are also in the works. The CD’s vast storage capabilities also lend itself to many broad- based multimedia applications, and it is quite possible that compact discs will become the common medium of data exchange for all audio, video, and computer applications.

Where To Learn More

Books

Brewer, Bryan and Ed Key. The Compact Disc Book. 1987.

Davidson, Homer L. Troubleshooting and Repairing the Compact Disc Player. 1989.

Pohlman, Ken. Principles of Digital Audio. 1985.

Schetina, Erik. The Compact Disc. 1989.

Williams, Gene B. Compact Disk Players. TAB Books, 1992.

Periodicals

Matzkin, Jonathan, Rock Miller, Gayle C. Ehrenman, et al. “CD-ROM Drives: Finally Up to Speed,” PC Magazine. October 29, 1991, p. 283.

Ranada, David. “Loose Bits,” High Fidelity. March, 1986, p. 22.

Shah, Prasanna. “Music of the Bitstream,” Audio. January, 1991, p. 56.