Background

The term “handgun” refers to any small firearm intended for use with one hand only. Currently, the two most important types of handguns are revolvers and automatic pistols. The key distinction between the two is that the former contains a cylindrical magazine (the firearm compartment from which cartridges, or bullets, are fed into the barrel) with multiple chambers that enable the shooter to fire repeated shots without pausing to reload. An automatic (self-loading) pistol feeds cartridges into the barrel from a detachable magazine that is inserted through the bottom of the butt (the gun’s handle). This type of pistol utilizes some of the recoil force from each cartridge firing to feed the next cartridge into its single chamber. As the two varieties differ widely in design and production, this article will concentrate on the revolver.

The earliest firearms ensued from the invention of black powder, a precursor of gunpowder developed in China during the ninth century A.D.; among other things, the Chinese apparently used their invention to propel primitive rockets. The recipe and uses for black powder were eventually transmitted to Europe by Mongol conquerors, and it was the Europeans who perfected the substance during the fourteenth century. Within one hundred years, the first small arms were being developed. However, early handguns remained troublesome for several centuries. For one thing, very few people could shoot them accurately (sighting targets proved easier with the long barrel of a musket to serve as a guide). Another problem was that their firepower had to be minimal if soldiers were to fire them with one hand. Until the mid-eighteenth century, most handguns could hold only one cartridge at a time, and this had to be loaded through the gun’s muzzle (barrel).The handgun became vastly improved in 1835, when Samuel Colt patented the first workable revolver, which became known as the cap-and-ball. Although Colt’s handgun still had to be front-loaded, its revolving cylinder contained five or six chambers, and the shooter advanced it automatically by cocking the hammer (earlier models had required shooters to align each chamber and depress the hammer separately). Later improvements yielded a cartridge revolver that did not have to be loaded through the muzzle, better ejection designs, and double-action cocking mechanisms.

By the end of the nineteenth century, when handguns incorporating these innovations were being mass produced, the revolver had reached its mature form. It remained the weapon of choice for military personnel until the second decade of the twentieth century, when it was replaced by automatic pistols. Although many predicted that the advent of the automatic model would render the revolver obsolete, it has remained popular. Today, revolvers continue to be used alongside automatic pistols by police officers, members of the armed forces, and target shooters throughout the world.

(Most revolver parts begin as steel or stainless steel blanks that are forged into close approximations of the desired parts. In forging, a heated blank is put into a forging press and impacted with several hundred Ions of force. This impact forces the metal into the forging die, a steel block with a cavity shaped like the part being produced. After annealing or heat treating the parts, they undergo basic machining processes such as milling, drilling, and tapping. Modern machining centers are automated, computer-controlled devices.)

Design

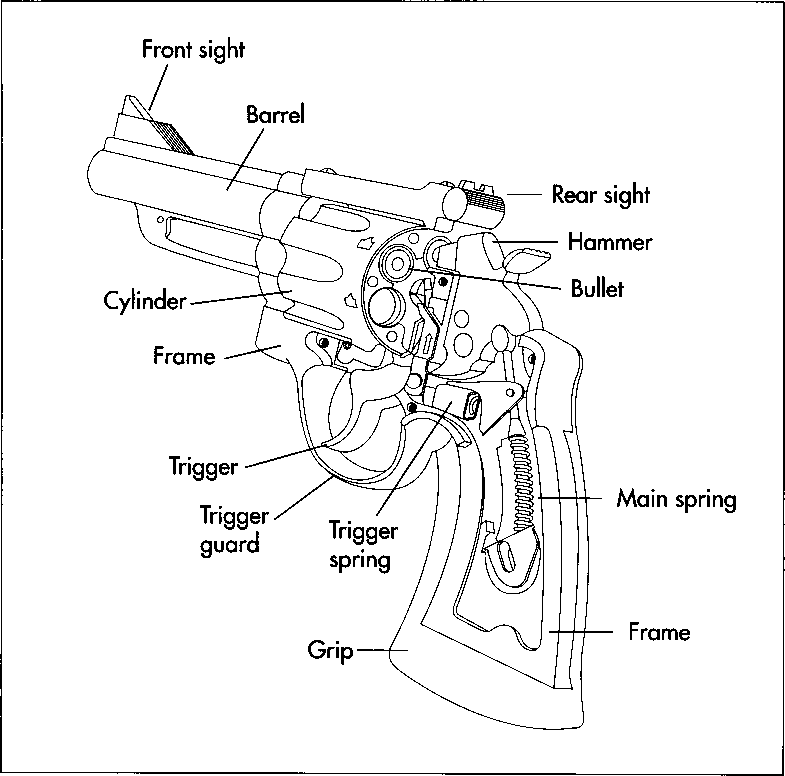

To understand how a revolver is made, it is important to know how each subsystem functions within the weapon. A revolver contains four main subsystems: the Frame Group; the Cylinder, Extractor, and Crane Group; the Barrel and Sight Group; and the Trigger, Timing Hand, and Hammer Group.

The Frame Group consists of the main frame, the trigger guard, and the hand grip. Its purpose is to provide a strong frame to contain the powerful force of the cartridge discharge, position the shooter’s hand correctly, and insure that the trigger functions precisely. Designs vary slightly due to manufacturers’ patents, but the operation is basically the same. Some frames have a removable sideplate that provides access to the trigger group, while others insert the trigger group as a separate assembly though the bottom of the frame. All modem revolvers utilize a frame design incorporating a solid top strap that connects the top of the grip area to the barrel mounting area, reinforcing the structural integrity of the frame.

The Cylinder, Extractor, and Crane Group consists of the cylinder itself, the shaft upon which it rotates, the extractor, the extractor shaft, a return spring, and the crane. The cylinder commonly contains six chambers for six cartridges of the correct caliber arranged in a circle. The rim, or outer edge of the cartridge base, rests upon a semicircular ledge formed by the extractor, which contains six small depressions in the center. The outside of the cylinder has six corresponding locking grooves. The cylinder rotates on the cylinder pin, which locks into the frame on one end and the crane on the other end. While the inside of the frame supports the base of the cartridge, the forcing cone on the barrel helps the bullet accurately jump the gap between the cylinder face and the barrel.

The Barrel and Sight Group is very important to the accuracy of the weapon. Threaded onto the frame, the barrel receives the bullet from the chamber upon firing. Inside, the barrel is rifled, or inscribed with a series of grooves that impart a stabilizing spin to bullets as they leave the gun. The sights consist ,of a Rear Sight with its groove or notch and a Front Sight which is typically shaped like a blade or post. The notch and the top of the blade, which can be adjusted, are aligned to help shooters aim. Most high quality revolvers feature sights purchased from companies whose specialty is fine mechanisms. Optical sights, low-and no-light sights, and lasers are also available.

The Trigger Group is best explained by describing the firing sequence, initiated when the shooter pulls back on the hammer spur. This action compresses, or cocks, the hammer spring and pushes the timing hand connecting the hammer to the trigger group into an extractor depression, rotating the cylinder to align that chamber and the barrel. The trigger mechanism latch engages the locking grooves, stopping further rotation and securing the cylinder for firing. At the end of the travel, the hammer is latched by the trigger sear and held ready for firing. When the trigger is fully depressed, the hammer unlatches from the trigger sear and is propelled forward by the hammer spring. This energy is transmitted to the firing pin, which strikes the primer of the cartridge, firing the weapon. This sequence of firing is called single action.

With the advent of the double action design, a connection bar was used to allow the trigger to rotate the cylinder, cock the hammer, and complete the firing in one motion. This design promoted an increase in rate of firepower and simplified the draw and fire situation. Most modem revolvers are of the double action design. After firing, the shooter releases the trigger. The trigger spring then returns the trigger to the forward position and forces the hand and latch to retract within the frame in preparation for the next shot. Once the cartridges have been fired, the cylinder latch on the side of the frame is pressed, disengaging the cylinder pin from the frame. This allows the entire assembly to swing out of the frame on the crane for reloading. The extractor shaft is pressed, lifting the cartridge cases out of their chambers, after which the cylinder spring returns the extractor to the cylinder. Live cartridges are again loaded and the cylinder is then simply pushed back into the frame, where the cylinder pin spring latches it back into place

(The barrel of the revolver contains rifling—a series of grooves witfi a precise twist that cause the bullet to spin as it exits the gun. To produce the rifling, a worker draws a broach-like cutting tool through the barrel blank repeatedly, removing metal to approximately .01 inch deep. In an alternative method called “button rifling,” a hardened form tool is drawn through the barrel blank under high force, displacing the metal in the grooves without cutting. This is similar in some respects to the forging operation, only it is done without heating the barrel.)

Raw Materials

With the exception of the grips, which may be wood or plastic, nearly all components of the revolver are metal. Steel was the primary metal until changes in its availability and advances in other metals rendered them more desirable. For example, during the 1860s, the disruption in the steel supply caused by the Civil War led to the use of brass for revolver frames. During World War II, the need for a lightweight weapon for use by aircraft crews brought about the use of a aluminum alloy frame. The stainless steel frame and barrel soon followed, improving corrosion resistance and reducing maintenance.

The Manufacturing Process

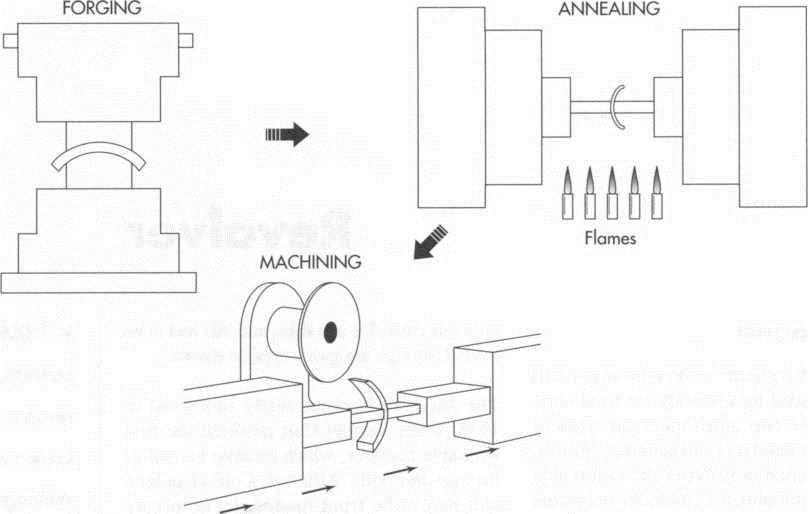

Forging the components

1 The major components of most revolvers begin as a group of steel or stainless steel blanks that are forged into close approximations of the desired parts. The basic shape of each part is formed by placing a heated blank of material into a forging press and impacting it with several hundred tons of force. This impact forces the metal into the forging die, a steel block with a cavity shaped like the part being produced. Sometimes, multiple strikes by the press are required, each with a more precise die than the previous step. The resulting part is both extremely strong and very similar to final shape.

Annealing and machining

2 After forging, the flow patterns of the metal must be stabilized by heat treating. This procedure consists of reheating the parts in a controlled atmosphere to relieve internal stresses without reducing the metal’s inherent strength.

3 Machining can now begin on the frame, cylinder, and other component parts. Most modem revolvers are manufactured on automated, computer-controlled machining centers and lathes. However, a number of manufacturers have had such excellent service and results with some of their machines that they continue to utilize fifty-year-old equipment. Regardless of whether older or modem equipment is used, the basic process actions of milling, drilling, and tapping are essentially the same. The tolerances on this machining must be held within one or two thousandths of an inch. All of the components, from the screws to the trigger, are machined using similar processes.

4 To effectively machine the raw forging, a worker clamps it into a holding apparatus that secures the part during machining. Properly designed fixtures also contain tool guides and bushings to support the cutting tool and increase accuracy. Many of the operations performed will require several specialized fixtures. Cylinders, screws, shafts, and barrels are made on lathes while frames, side plates, sights, and triggers are made on a milling and machining center.

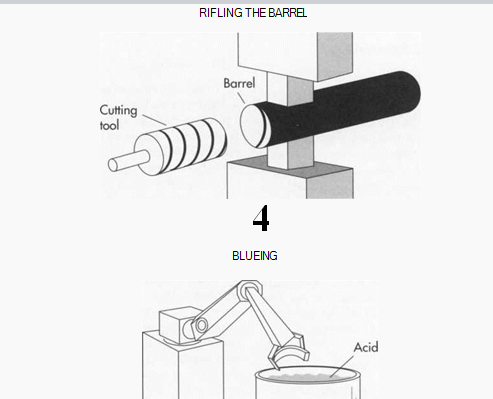

Rifling the barrel

5 One of the most unique processes is the rifling of the barrel. Rifling is essentially a series of grooves within the barrel. These grooves have a precise twist that, through contact with the bullet circumference, causes the bullet to spin during firing. This rate of twist is about 1 turn in 16 inches (40.6 centimeters). To produce the rifling, a worker subjects the barrel to either the cutting or the button rifling process. Cutting is accomplished by drawing a broach-like cutting tool through the barrel blank repeatedly, removing metal to approximately .010 inch (.025 centimeter) deep. Cutting marks and other scratches within the rifling can impair accuracy by damaging the bullet, which throws it out of balance. However, one advantage of these marks is that they are different in every gun barrel, producing unique rifling imprints on the bullets they fire. This is how law enforcement specialists match bullets to the gun that fired them.

6 Button rifling refers to an operation in which a hardened form tool is drawn through the barrel blank under high force, displacing the metal in the grooves without cutting. This is similar in some respects to the forging operation, only it is done without heating the barrel. The advantages of button rifling are increased production, no chip formation, and improved surface quality.

Applying protective coatings

7 After machining, the metal surfaces of most steel or aluminum weapons receive a protective coating to reduce corrosion. Commonly referred to as blueing, this process entails submersing the parts in tanks of acid and other chemicals. In these vats, the chemicals react with the metal to produce a durable barrier against the elements. Chrome and gold plating, parkerizing, and anodizing (for aluminum) are some variants of the blueing process, while plating, another means of applying a protective coat, is accomplished by setting up an electric current between the parts and the supply anode, which consists of another type of metal. The electrical path carries molecules of the plating metal to the component, where they bond very tightly to the surface.

(A revolver contains 4 main subsystems: the Frame Group; the Cylinder, Extractor, and Crane Group; the Barrel and Sight Group; and the Trigger, Timing Hand, and Hammer Group. Most modem revolvers are of the double action design, in which the trigger rotates the cylinder, cocks the hammer, and completes the firing in one motion.)

Assembly

8 The entire weapon is assembled by one person who fits all of the components, many of them manually. While dimensional control has improved significantly over the past twenty years, the timing of the trigger and hand mechanism and the crispness of the trigger pull are still set by hand. Most manufacturers have grades of fitting quality; for example, the trigger pull of a service weapon that will be used by police is set heavier than that of a target or specialty handgun. One would expect to exert a more determined effort to discharge a weapon in a law enforcement setting, while at the target range the lighter trigger pull is desirable to increase accuracy. Once the weapon has been put together, any necessary filing, polishing, and tuning will be performed before testing.

Quality Control

After assembly and fine tuning, the weapon is dry fired (without ammunition) and checked for function before being sent to the firing line for proof firing. The first phase of the proof firing process entails inspecting and recording the gun’s trigger weighting, sights, and cylinder spacing. Next, the gun is loaded with special ammunition and fired. Industry standards dictate the types and relative power of the proofing cartridges. They are typically heavier charged than the service cartridge, assuring that any weakness in the gun will be detected before it is placed into service. The gun is then packaged and shipped to law enforcement agencies, military contractors, and federally licensed weapons dealers.

The Future

From the manufacturing standpoint, the handgun is still making use of new materials and processes, even though the design is quite mature. With the advent of investment castings, net shape forgings, and lightweight alloys, revisions to the standard design will continue. From a social perspective, the handgun has been the center of increasing debate since the 1960s. Many people have contended that limiting access to guns and ammunition would reduce violence in the United States. However, such proposals have been counterbalanced by a popular interpretation of the Second Amendment to the Constitution, which many believe guarantees individual citizens the right to bear arms. This debate continues in both the media and various state and federal legislatures. As of today, revolvers remain popular with law enforcement officers and military personnel. In addition, ordinary citizens can purchase and utilize them with relative ease, as the constraints that some states have recently imposed upon gun purchasers are generally limited to mandatory waiting periods that enable salespeople to perform background checks.

Where To Learn More

Books

Gould, A. C. Modem American Pistols and Revolvers. Wolfe Publishing, 1987.

Grennell, Dean A. Handgun Digest, 2nd ed. DBI Books, 1991.

Long, Duncan. Combat Revolvers: The Best (and Worst) Modern Wheel guns. Paladin Press, 1989.

Newton, Michael. Armed and Dangerous: A Writer’s Guide to Weapons. Writer’s Digest Books, 1990.

Pistols and Revolvers: A Handbook. Gordon Press, 1989.

Wood, J. B. Gun Digest Book of Firearms Assembly—Disassembly, Part II: Revolvers. DBI Books, 1990.