Background

While most footwear protects and supports the foot, the running shoe goes beyond what one would expect of the ordinary shoe. Its advantages have been the subject of intense scrutiny in recent years, a focus that results from an increasingly health- and leisure-conscious population in general, and from the popularity of running in particular. As more people have become involved in the sport, more and more varied equipment has become available to runners. Consequently, the running shoe has evolved quite dramatically over the past 15 years.

Running as a sport can be traced back to the ancient Greeks, who advocated a culture based on sound bodies and sound minds. During Greek athletic contests, runners competed barefoot and often naked. Later, the Romans mandated that their messengers wear thin-soled sandals. As shoemaking evolved through the centuries, leather became and remained the favored material because of its durability. However, the first references to shoes designed specifically for running don’t appear until 1852, when historians noted a race in which runners wore shoes with spiked soles. In 1900, the first sneaker, or all-purpose athletic shoe, was designed. Made primarily of canvas, this sneaker featured a rubber rim made possible by Charles Goodyear’s 1839 discovery of vulcanized rubber. Known about for 1,000 years, rubber was finally rendered commercially useful when Goodyear heated and combined it with sulphur, thereby preventing it from hardening and losing its elasticity. In athletic shoes, rubber helped to cushion the impact of running on hard surfaces. However, it did not last as a shoemaking material: it was not durable, and leather returned as the preferred material for running shoes. Yet leather wasn’t the ideal fabric, either. In addition to being expensive, leather shoes caused chafing, and runners had to purchase chamois liners to protect their feet. A Scotsman known as “Old Man” Richings provided some relief when he invented a customized shoe designed with a seamless toe box (a piece of material inserted between the toe cap and the shoe lining and treated with a hardening agent, the toe box protects the toes against rubbing).

In 1925, Adolph Dassler, a German shoemaker, decided to concentrate on athletic shoes, and founded a business with his brother, Rudolph, to do so. The Dasslers’ running shoes provided both arch support and speed lacing, and their high-quality products attracted prominent athletes including some Olympians: Jesse Owens is re-ported to have worn Dassler shoes during the 1936 games in Munich. The brothers later formed separate companies—Adolph, the Adidas company and Rudolph, the Puma company. Another manufacturer of running shoes during the mid-twentieth century was Hyde Athletic of New England, although the company specialized in football shoes. A 1949 description of Hyde’s running shoe said that it featured kangaroo leather, a welt construction (a welt is a strip used to connect the upper to the sole—see “Design” section below), an elastic gore closure (a triangular piece of leather on the upper part of the shoe), and a leather sole covered in crepe rubber, a crinkly form of the material used especially for shoe soles. One of the most unusual running shoes of the mid-twentieth century was worn by the Japanese runner who won the 1951 Boston Marathon. Called the Tiger, his shoe was modeled after a traditional Japanese shoe that enclosed the big toe separately from the other toes.

During the 1960s, a company called New Balance began to examine how running impacts the foot. As a result of this research, New Balance developed an orthopedic running shoe with a rippled sole and wedge heel to absorb shock. As running became more popular and joggers more knowledgeable, the demand for footwear that would help prevent injuries increased. Many runners also began to request shoes that provided support in a lightweight construction, and nylon, invented during World War II, consequently began to replace the heavier leather and canvas materials previously used to make running shoes. Today, however, the comfort of the running shoe isn’t known only to the jogger. Running shoes can be spotted on just about anyone who wants comfort in a shoe. In fact, running shoes have ceased to surprise when they appear on the feet of otherwise formally-attired office workers en route to work. In 1990, consumers spent $645 million for 15 million pairs of running shoes, and experts note that the majority bought were used for comfort rather than running.

Raw Materials

Running shoes are made from a combination of materials. The sole has three layers: insole, midsole, and outsole. The insole is a thin layer of man-made ethylene vinyl acetate (EVA). The components of the midsole, which provides the bulk of the cushioning, will vary among manufacturers. Generally it consists of polyurethane surrounding another material such as gel or liquid silicone, or polyurethane foam given a special brand name by the manufacturer. In some cases the polyurethane may surround capsules of compressed air. Outsoles are usually made of carbon rubber, which is hard, or blown rubber, a softer type, although manufacturers use an assortment of materials to produce different textures on the outsole.

The rest of the covering is usually a synthetic material such as artificial suede or a nylon weave with plastic slabs or boards supporting the shape. There may be a leather overlay or nylon overlay with leather attachments. Cloth is usually limited to the laces fitted through plastic eyelets, and nails have given way to an adhesive known as cement lasting that bonds the various components together.

Design

The last 15 years have witnessed great changes in the design of the running shoe, which now comes in all styles and colors. Contemporary shoe designers focus on the anatomy and the movement of the foot. Using video cameras and computers, they analyze such factors as limb movement, the effect of different terrains on impact, and foot position on impact. Runners are labeled pronators if their feet roll inward or supinators if their feet roll to the outside. Along with pressure points, friction patterns, and force of impact, this information is fed into computers which calculate how best to accommodate these conditions. Designers next test and develop prototypes based on their studies of joggers and professional runners, readying a final design for mass production.

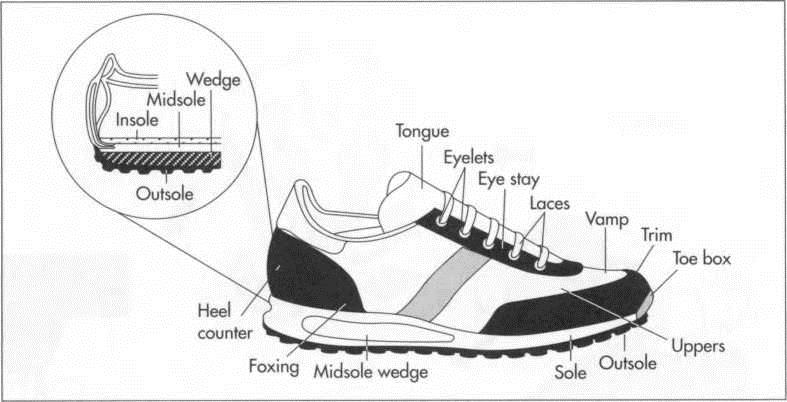

A running shoe may have as many as 20 parts to it, and the components listed below are the most basic. The shoe has two main parts: the upper, which covers the top and sides of the foot, and the bottom part, which makes contact with the surface.

As we work our way around the shoe clockwise, starting at the front on the upper part is the featherline, which forms the edge where the mudguard (or toeguard) tip meets the bottom of the shoe. Next is the vamp, usually a single piece of material that gives shape to the shoe and forms the toe box. The vamp also has attachments such as the throat, which contains the eyestay and lacing section. Beneath the lacing section is the tongue, protecting the foot from direct contact with the laces. Also attached to the vamp along the sides of the shoe are reinforcements. If sewn on the outside of the shoe these reinforcements are called a saddle; if sewn on the inside, they are called an arch bandage. Further towards the back of the shoe is the collar, which usually has an Achilles tendon protector at the top back of the shoe. The foxing shapes the rear end of the shoe. Underneath it is a plastic cup that supports the heel, the heel counter.

The bottom has three main parts, outsole, midsole, and wedge. The outsole provides traction and absorbs shock. The midsole is designed specifically for shock absorption, and the wedge supports the heel. Located inside the shoe, the insole also contains the arch support (sometimes called the arch cookie).

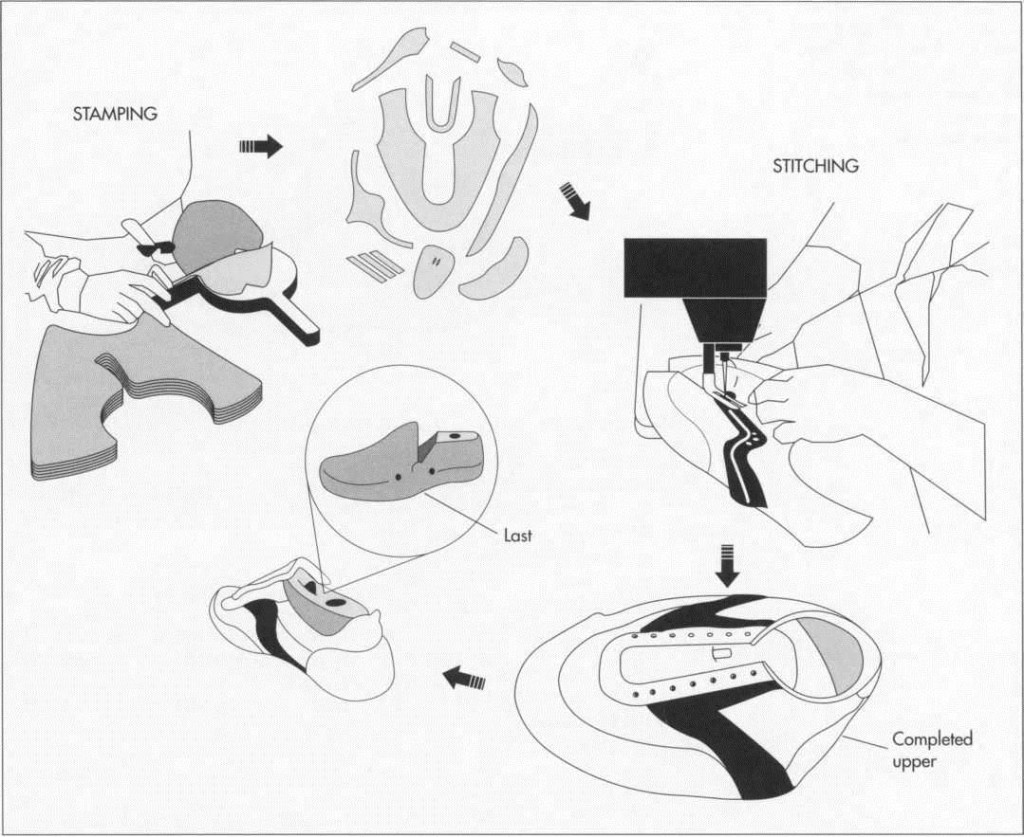

(The first step in running shoe manufacture involves die cutting the shoe parts in cookie cutter fashion. Next, the pieces that will form the upper part of the shoe are stitched or cemented together. At this point, the upper looks not like a shoe but like a round hat; the extra material is called the lasting margin. After the upper is heated and fitted around a plastic mold called a last, the insole, midsole, and outsole are cemented to the upper)

The Manufacturing Process

Shoemaking is a labor-intensive process, and the cost of producing the many components of the running shoe reflect the skilled labor necessary. Each phase of production requires precision and skills, and taking shortcuts to reduce costs can result in an inferior shoe. Some running shoes (known as sliplasted shoes) have no insole board. Instead, the single-layer upper is wrapped around both the top and the bottom portions of the foot. Most running shoes, however, consist of an insole board that is cemented to the upper with cement. This section will focus on cement-lasted shoes.

Shipping and stamping the fabric

1 First, prepared rolls of synthetic material and rolls of dyed, split, and suede leather (used as part of the foxing) are sent to the factory.

2 Next, die machines stamp the shoe shapes, which are then cut out in cookie cutter fashion with various markings to guide the rest of the assembly. After being bundled and labeled, these pieces are sent to another part of the factory where they’ll be stitched.

(Completed running shoes are quality tested using procedures developed by the Shoe and Allied Trades Research Association. Defects that are checked for include poor lasting, incomplete cement bonding, and stitching errors)

Assembling the upper and the insole

3 The pieces that will form the upper part of the shoe are stitched or cemented together and the lace holes punched out. These pieces include the feather line, the vamp, the mudguard, the throat (with eyestay and lacing section), the tongue, reinforcements such as the saddle or arch bandage, the collar (with Achilles tendon protector), the foxing, and the logo. At this point, the upper looks not like a shoe but like a round hat, because there is extra material—called the lasting margin—that will be folded underneath the shoe when it gets cemented to the sole.

4 Next, the insole is stitched to the sides of the upper. Stiffening agents are then added to the heel region and toe box, and an insole board is inserted.

Attaching the upper and bottom parts

5 The completed upper is heated and fitted around a last, a plastic mold that forms the final shape of the shoe. An automatic lasting machine then pulls the upper down over the last. Finally, a cement nozzle applies cement between the upper and insole board, and the machine presses the two pieces together to bond them. The upper now has the exact shape of the finished shoe.

6 Pre-stamped and cutout forms of the midsole and outsole or wedge are layered and cemented to the upper. First, the outsole and midsole are aligned and bonded together. Next, the outsole and midsole are aligned with the upper and placed over a heater to reactivate the cement. As the cement cools, the upper and bottom are joined.

7 The shoe is removed from the last and inspected. Any excess cement is scraped off.

Quality Control

Manufacturers can test their materials using procedures developed by the Shoe and Allied Trades Research Association (SATRA), which provides devices designed to test each element of the shoe. Once the shoe is complete, an inspector at the factory checks for defects such as poor lasting, incomplete cement bonding, and stitching errors. Because running can cause a number of injuries to the foot as well as to tendons and ligaments in the leg, another test is currently being developed to evaluate a shoe’s shock absorption properties.

The Future

In the near future, experts predict refinements of current designs and manufacturing processes rather than radical breakthroughs. Within the next ten years, athletic shoe sizing should become standard worldwide. Designers will continue to seek lighter weight materials that provide better support and stability with further use of gels and air systems. Electronic components will also be built into the running shoe, so that information about physical characteristics and developments can be measured with a microchip and later downloaded into a computer. Another feature that is already beginning to appear is the battery-operated lighting systems to accommodate the evening jogger. As consumers continue to spend millions for the comfort of running shoes, manufacturers of the ordinary shoe will continue to compete for these dollars by applying running shoe design principles to everyday shoes.

Where To Learn More

Books

Cavanagh, Peter R. The Running Shoe Book. Macmillan, 1980.

Cheskin, Melvyn P. The Complete Handbook of Athletic Footwear. Fairchild Books, 1986.

Nigg, Benno M. Biomechanics of Running Shoes. Human Kinetics Publishers, Inc., 1986.

Rossi, William A., ed. The Complete Footwear Dictionary. Krieger Publishing, 1993.

The Shoe in Sport. Mosby-Year Book, 1989. Periodicals

Begley, Sharon. “The Science in Sports.” Newsweek. July 27, 1992, p. 58.

“Running Shoes: The Sneaker Grows Up.” Consumer Reports. May, 1992, pp. 308-314.

Ireland, Donald R. “The Shocking Truth about Athletic Footwear.” ASTM Standardization News. June, 1992, pp. 42¬45.

Murray, Charles J. “Composite Insole Absorbs Shock in Running Shoes.” Design News. May 2, 1988, p. 100.

Wolkomir, Richard. “The Race to Make a ‘Perfect’ Shoe Starts in the Laboratory.” Smithsonian. September, 1989, p. 94.